Plants and

Equipment

- TOP

- Plants and Equipment

- Introduction to Plants and Equipment

Introduction to Plants and Equipment

Distillation equipment

We have all of our precision distillation apparatuses (0.1 L - 10,000 L) designed in-house. Equipment for research and development, and plant equipment, can operate continuously 24-hours a day.

Boiler equipment

Heat transfer boilers (16 units)

Steam boilers (2 units)

Storage equipment

Underground tank storage (17 tanks (24 kL))

Indoor storage space (Capacity of 500 x 200 L drums)

Freezers and refrigerators (Capacity of 10 x 200 L drums)

Large-scale distillation equipment

As of April 2023

← The table below can slide to the left or right. →

| No.A-1 | No.A-2 | No.C-2 | No.C-3 | No.A-4 | No.A-5 | No.B-7 | No.B-8 | No.C-1 | |

|---|---|---|---|---|---|---|---|---|---|

| Distillation still | 10,000L | 10,000L | 7,000L | 7,000L | 3,000L | 3,000L | 3,000L | 3,000L | 3,000L |

| Equipment material | SUS304 | SUS304 | SUS316L | SUS316L | SUS304 | SUS304 | SUS316L | SUS316L | SUS304 |

| Number of theoretical stages | 40 stages | 40 stages | 80 stages | 60 stages | 10 stages | 60 stages | 40 stages | 80 stages | 60 stages |

| Vacuum degree | 100Pa~ | 100Pa~ | 100Pa~ | 100Pa~ | 100Pa~ | 100Pa~ | 100Pa~ | 100Pa~ | 100Pa~ |

| Handling temperature | ~280℃ | ~280℃ | ~330℃ | ~330℃ | ~280℃ | ~280℃ | ~280℃ | ~280℃ | ~330℃ |

| Cooling temperature | 10℃~ | 10℃~ | 0℃~ | 0℃~ | 0℃~ | 0℃~ | 10℃~ | 10℃~ | 0℃~ |

| Handling boiling point | ~100℃ | ~100℃ | ~100℃ | ~100℃ | ~100℃ | ~100℃ | ~100℃ | ~100℃ | ~100℃ |

Method: batch type/Filling ingredients: regular/Heat source: medium oil or steam

Mid-scale distillation equipment

As of April 2023

← The table below can slide to the left or right. →

| No.A-6 | No.A-7 | No.C-6 | No.C-7 | No.C-4 | No.C-5 | No.C-8 | |

|---|---|---|---|---|---|---|---|

| Distillation still | 400L | 400L | 400L | 400L | 200L | 200L | 200L |

| Equipment material | SUS316L | SUS316L | SUS304 | SUS304 | SUS316L | SUS316L | SUS304 |

| Number of theoretical stages | 80 stages | 20 stages | 60 stages | 〜10 stages | 60 stages | 80 stages | 〜5 stages |

| Vacuum degree | 50Pa~ | 50Pa~ | 50Pa~ | 50Pa~ | 50Pa~ | 50Pa~ | 50Pa~ |

| Handling temperature | ~330℃ | ~330℃ | ~280℃ | ~330℃ | ~330℃ | ~330℃ | ~330℃ |

| Cooling temperature | 0℃~ | 0℃~ | 0℃~ | 0℃~ | 0℃~ | 0℃~ | 0℃~ |

| Handling boiling point | ~120℃ | ~120℃ | ~120℃ | ~120℃ | ~120℃ | ~120℃ | ~120℃ |

Method: batch type/Filling ingredients: regular/Heat source: medium oil or steam

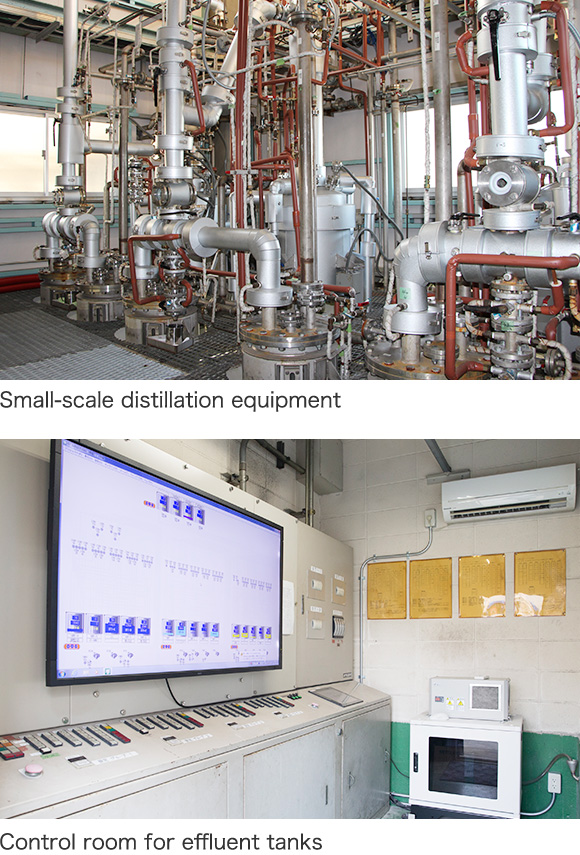

Small-scale distillation equipment

As of April 2023

← The table below can slide to the left or right. →

| No.F-2 | No.F-1 | No.F-3 | |

|---|---|---|---|

| Distillation still | 200L | 100L | 100L |

| Equipment material | SUS316L※1 | SUS304 | SUS304 |

| Number of theoretical stages | Simple distillation | Simple distillation | 80 stages |

| Vacuum degree | 30Pa~ | 30Pa~ | 30Pa~ |

| Handling temperature | ~180℃ | ~330℃ | ~330℃ |

| Cooling temperature | -10℃~ | -10℃~ | -10℃~ |

| Handling boiling point | Room temperature liquid only※2 | ~150℃ | ~150℃ |

Method: batch type/Filling ingredients: regular/Heat source: medium oil or steam

- ※1 PFA coating after fractionating column

- ※2 Consultation required for substances with melting points

Distillation equipment for research and development

As of April 2023

← The table below can slide to the left or right. →

| 50L | 20L | 10L | 3L | 1L | 0.5L | 0.3L | 0.1L | |

|---|---|---|---|---|---|---|---|---|

| Distillation still | 50L | 20L | 10L | 3L | 1L | 0.5L | 0.3L | 0.1L |

| Equipment material | glass | glass | glass | glass | glass | glass | glass | glass |

| Number of theoretical stages | 〜60 stages | more 〜100 stages | more 〜100 stages | more 〜100 stages | more 〜100 stages | 〜80 stages | 〜20 stages | Simple distillation |

| Vacuum degree | 20Pa~ | 10Pa~ | 10Pa~ | 10Pa~ | 10Pa~ | 10Pa~ | 10Pa~ | 10Pa~ |

| Handling temperature | ~350℃ | ~350℃ | ~350℃ | ~350℃ | ~350℃ | ~350℃ | ~350℃ | ~350℃ |

| Cooling temperature | -10℃~ | -15℃~ | -15℃~ | -15℃~ | -15℃~ | -15℃~ | -15℃~ | -15℃~ |

| Handling boiling point | ~150℃ | ~200℃ | ~200℃ | ~200℃ | ~200℃ | ~200℃ | ~200℃ | ~200℃ |

Method: batch type/Filling ingredients: regular or irregular/Heat source: medium oil or mantle heater